Industrial software development, consultancy, digital factory tools, standardisation, QS and SCADA

What we do?

With over 30 years of experience, Aber Industrial Solutions serves a diverse range of industrial clients, from large corporations to smaller businesses. We specialize in project management, consultancy, industrial HMI commissioning, SCADA control technology, quality assurance, software development, and PLC programming. Our approach tailors to the specific needs of each client, ensuring quality, reliability, and innovation. Partner with us for tailored, efficient solutions that cater to your unique industrial challenges.

Our Services

-

Consultancy

We offer our experience to consult or manage your projects.

-

Industrial apps

We develop software in the following fields:

• Fullstack Apps

• Desktop Apps

• Mobile Apps -

Quality Assurance

System acceptance and QS. Documentation Safety-relevant documents (measurement protocol according to BGV A3, CE certificate, risk assessment MSR technology). Control cabinet construction and system. Function test of the plant. Risk assessments of plants

-

HMI SCADA

We have created HMIs in all areas of the automotive industry and in the fields of mechanical engineering, mechanisation and the chemical industry. Our experience ranges from the adaptation of existing HMIs to the creation of SCADA standards.

We offer specialised solutions that complement existing SCADA systems and standards, large scale migration of SCADA systems and HMI project development. -

Automotive

Our HMI, SCADA and control technology projects have been realised in the following areas:

Body shop

Paint shop

Assembly

Application technology

Building services engineering

High bay storage

Marriage station

Transport tracking -

PLC Programming

PLC Programming in the following areas:

• Siemens Simatic Step 7

• Process technology

• Conveyor technology

• Mechanisation

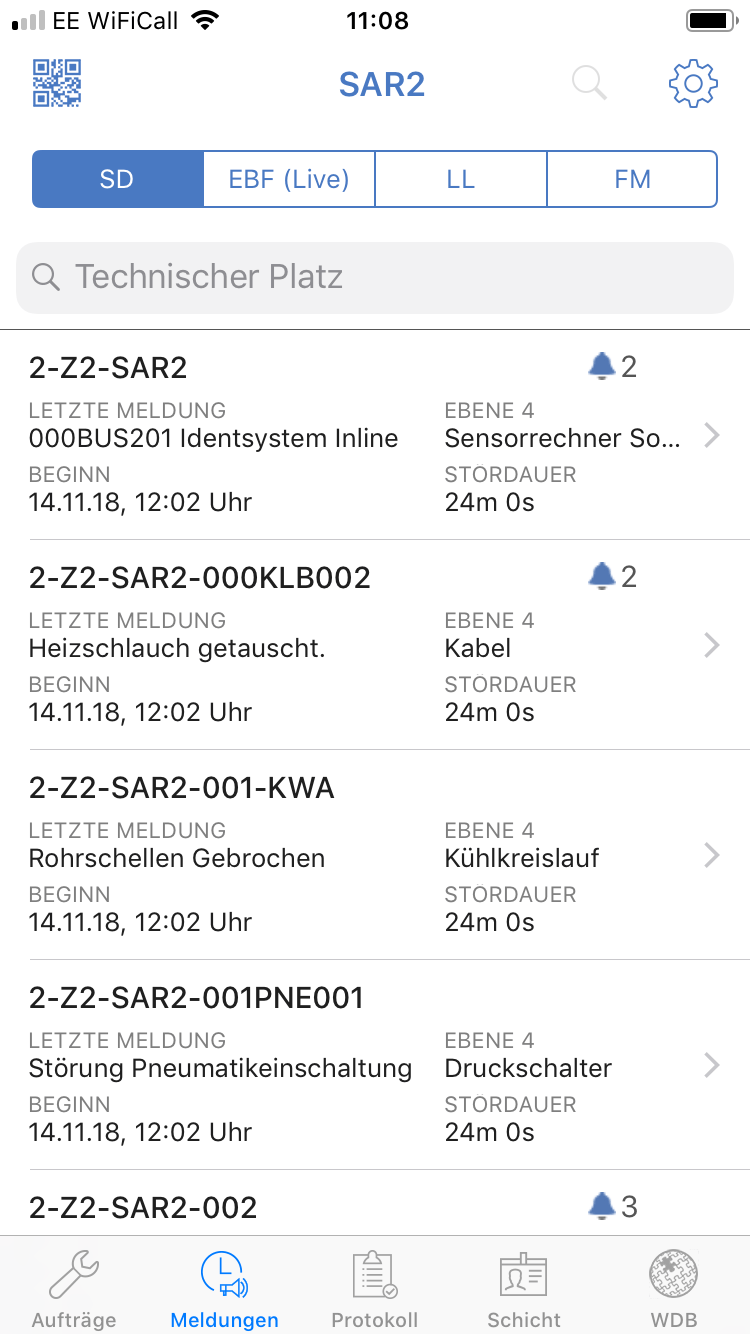

Maintenance iOS App

An iPhone app specially developed for maintenance to digitize production. With the help of this app, the maintenance technician can access information such as system faults quickly and in a targeted manner. Faults can be analysed and documented. The task management function reduces the administrative effort involved in maintenance. Foremen can assign tasks to their maintenance personnel and track the progress of the processing.

Technologies used for this app:

Swift, C#, C++, TCP, HTTP, SQL, Fullstack Web app

Industry maintenance mobile app functionality:

• Task management for maintenance staff

• Faults statistics

• QR code scanning of functional locations

• Display of upcoming and closed faults

• Fault documentation and Annotation

• Follow-up lists

• Export and import of images and PDF

• Shift handover

• Server administration

Automotive HMI projects

We specialise in HMIs and SCADA systems in a wide scope of areas in the automotive industry. We offer specialised solutions that complement existing SCADA systems including large scale migration of present systems and integration of new systems to coexist with existing plant standards. We have experience in developing and implementing factory SCADA standards.

Our HMI, SCADA and control technology projects have been realised in the following areas:

• Body shop

• Paint shop

• Assembly

• Application technology

• Building services engineering

• High bay storage

• Marriage station

• Transport tracking